SAE 660 Bronze (C93200)

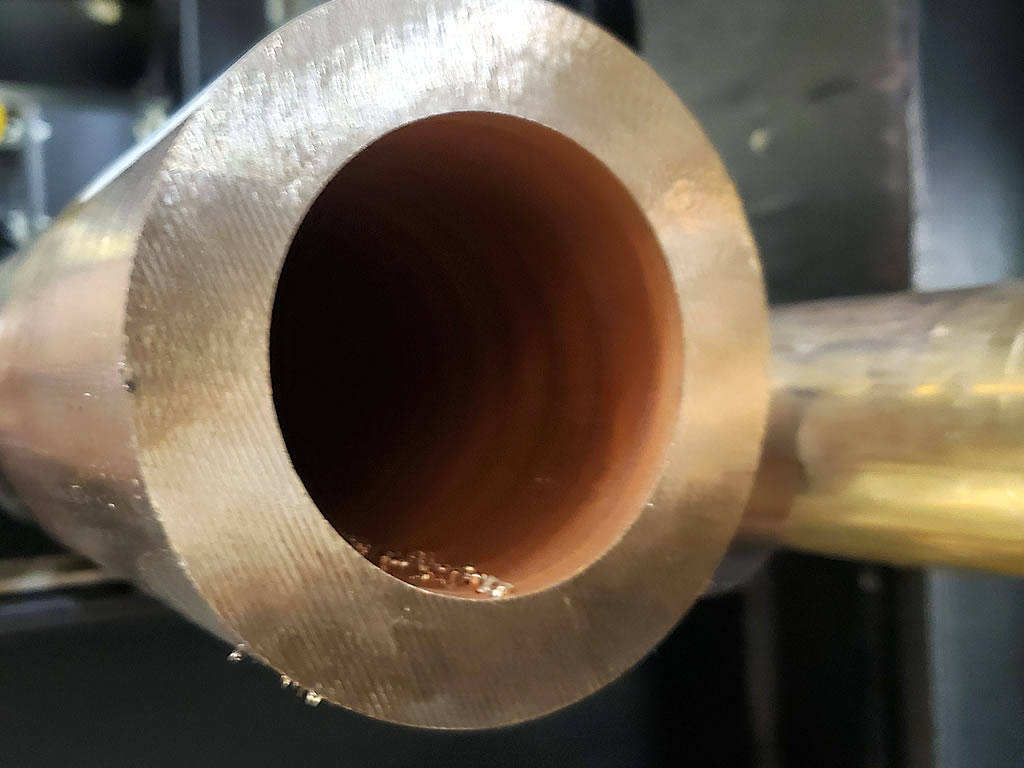

SAE660 leaded bronze is suitable for various engineering applications performed under medium loads whilst using adequate lubrication.

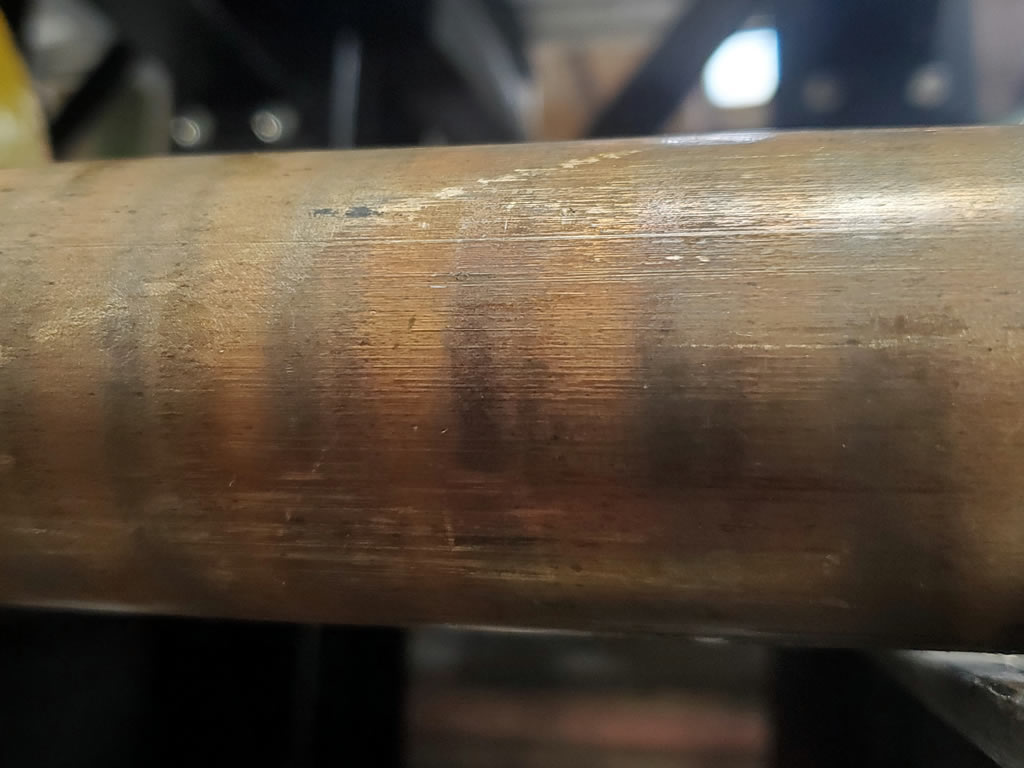

The alloy is a continuously cast leaded copper-based material known as leaded bronze. It is highly suited to pump and valve component manufacture due to the alloy's resistance to brine. SAE660 offers good sliding and dry-running properties and is not subject to dezincification. Our product also boasts excellent machinability characteristics.

Benefits:

Typical commercial applications include:

- Versatile - broad application usage

- Excellent anti-friction qualities

- Excellent machining properties

- Ideal in bushes and bearings under medium loads

Alternatives?

While SA660 leaded bronze is well known in the market, a natural alternative is available - SigmaBronze 7™ . SigmaBronze 7™ affords our customers the same characteristics and performance benefits of SAE660 leaded bronze, but we supply the alloy in metric sizes.

Material Specifications

Material Specifications: BS1400 LB4, C93200, SAE660, SigmaBronze 7

Applications

SAE660 find use in the production of valve and slide seating rings, hydraulic components, fuel and water pump bushes and in the manufacture of general-purpose bushes & bearings.

Stocked Products

We stock SAE660 leaded bronze in round bars, hollow bars, flat bars and plates. We also process these engineering materials in-house using our bar sawing, tube sawing and plate sawing services.

Product Summary

| Product | SAE 660 |

|---|---|

| Type | Leaded Bronze |

| Availability | Round bar, hollow bar, flat bar and plate |

| Benefits | Versatile - broad application usage, excellent anti-friction qualities, excellent machining properties, ideal in bushes and bearings under medium loads |

| Applications | Valve and slide seating rings, hydraulic components, fuel and water pump bushes, general-purpose bushes & bearings |

| Datasheet | SAE 660 - Technical Datasheet |

| Reference | Home/ Products/ Bronze Alloys/ SAE 660 |