Metal Billeting Services

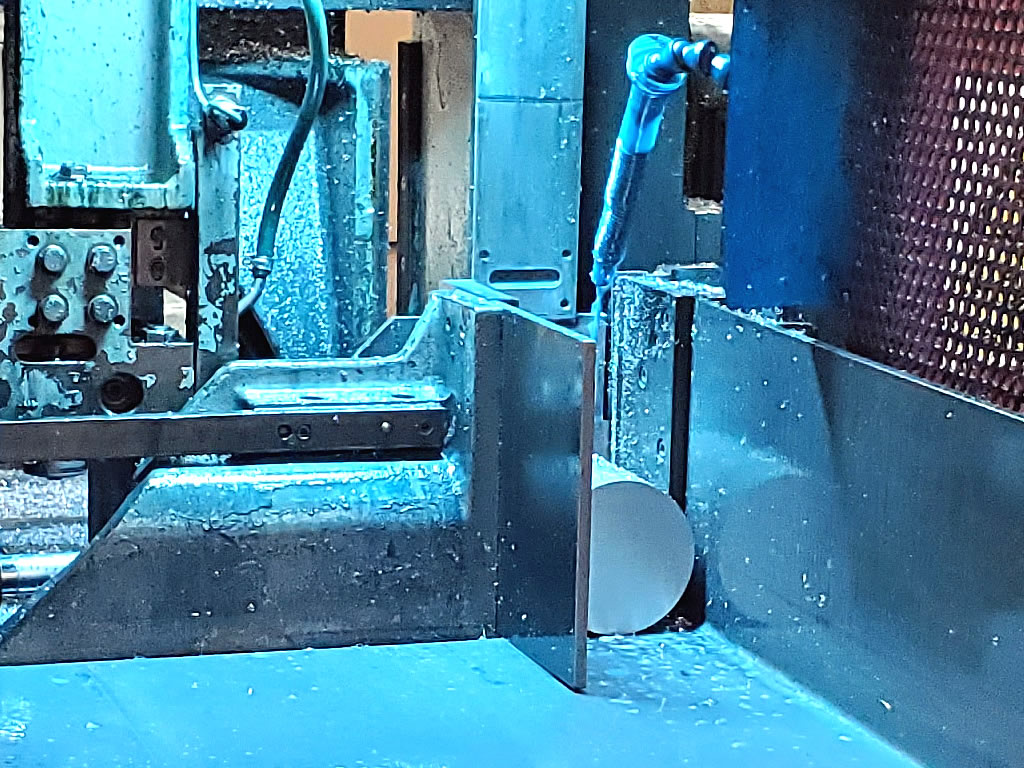

Our billeting services provide a value-added service where we cut alloy and plastic bars to specific lengths.

You may be purchasing full-size bar products and then having to cut them down into more manageable billets. Depending on your situation, this not only involves cost but, more importantly, can be potentially inconvenient.

Capabilities

We process bars to the following:

- Min. dia./section - 12.70mm (1/2"), max. dia./section - 520.7mm (20.5")

- Min. wall thickness - 1.5mm - 3mm (1/16" - 1/8")

- Blank tolerance - ± 0.30mm (± 0.012")

- Min. blank length - 6mm (5/16")

What we offer

Thames offers rod blanking options where we cut your products to the specific billet sizes you need. Our Group currently cuts over two million billets per year, so we can employ scale efficiencies that reduce our cutting costs to a minimum which we can pass on to our customers.

Options

We can handle solids, most sections and tubes without any marking or crushing. By combining our processing services with rapid response times, we supply you with supply chain options which are efficient and cost-effective.

Accuracy

We cut your solid bars accurately and to close tolerances to suit your size requirements. We also utilise our vehicle fleet to deliver our products to your destination.

Traceability

Our material stock carries a unique bar code for total material traceability. If the material is cut, the processed bars are assigned new bar codes. So regardless of whether the material is a stocked length or has been cut, complete traceability is assured.

Processing Services

| Type | Billeting |

|---|---|

| Services | Billeting / Bar Sawing / Rod Blanking |

| Diameter/Section | Min: 1/2" (12.70mm) - Max: 20.5" (520.7mm) |

| Blank Tolerance | ± 0.30mm (± 0.012") |

| Min. Blank Length | 5/16" (6mm) |

| Info Sheet | Thames Processing Info Sheet |

| Reference | Home/ Processing/ Billeting |