Outstanding Versatility

Copper is a highly versatile alloy - it can easily be combined with other alloys for deployment in virtually any application.

Only silver rivals copper for its superior conductivity, and copper offers good to excellent corrosive resistance. Since the material is also a central alloying element in bronze and brass, its use in commercial applications is widespread.

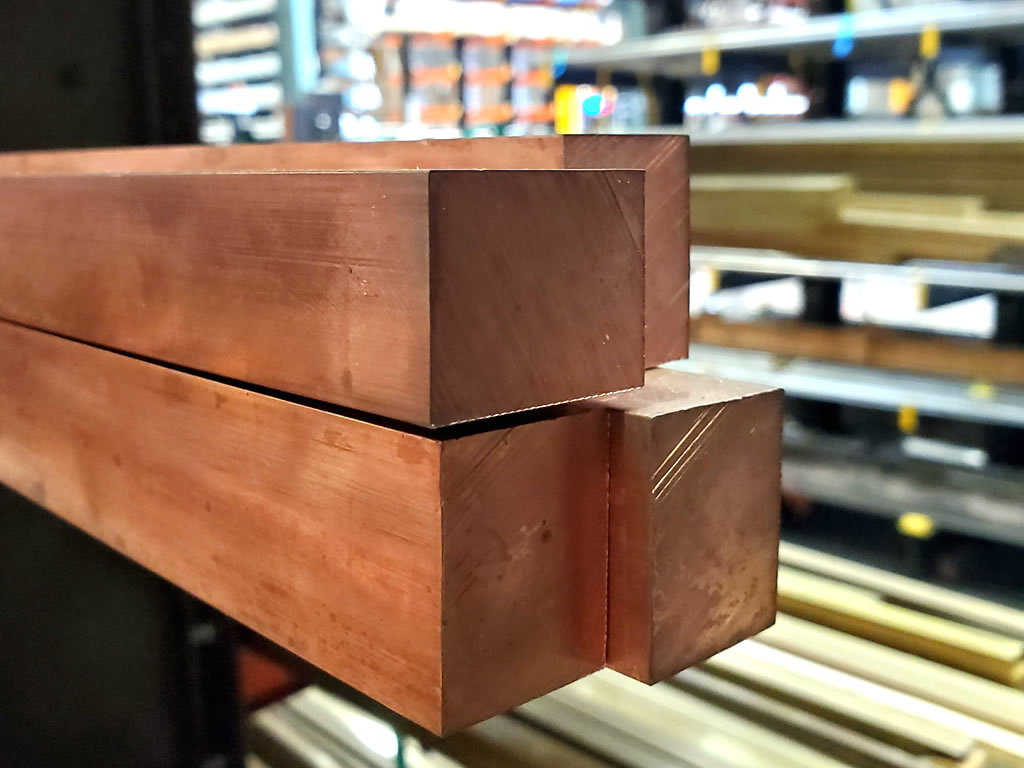

The machinability of copper is excellent, and the performance characteristics of the alloy are further enhanced through variations in product chemistry and alloy production.

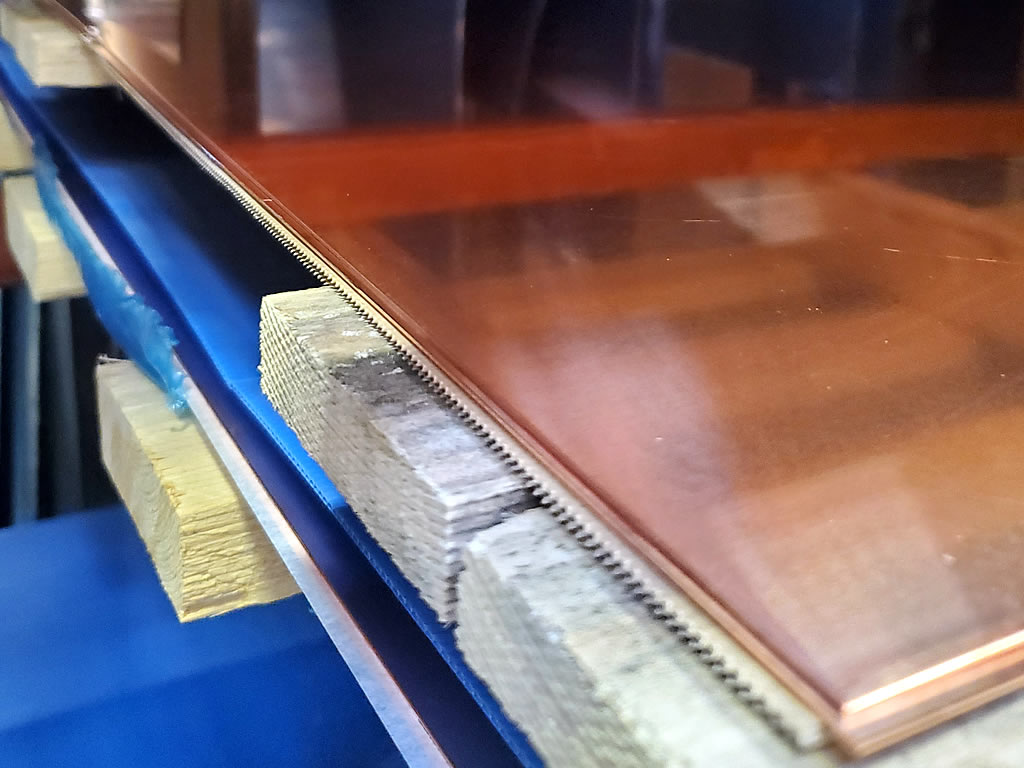

Copper is also used extensively in construction for architectural and aesthetic purposes. Electronics is also a primary beneficiary due to the alloy's electrical and thermal conductive capabilities.

We supply copper in various grades, shapes and sizes to suit your engineering requirements.