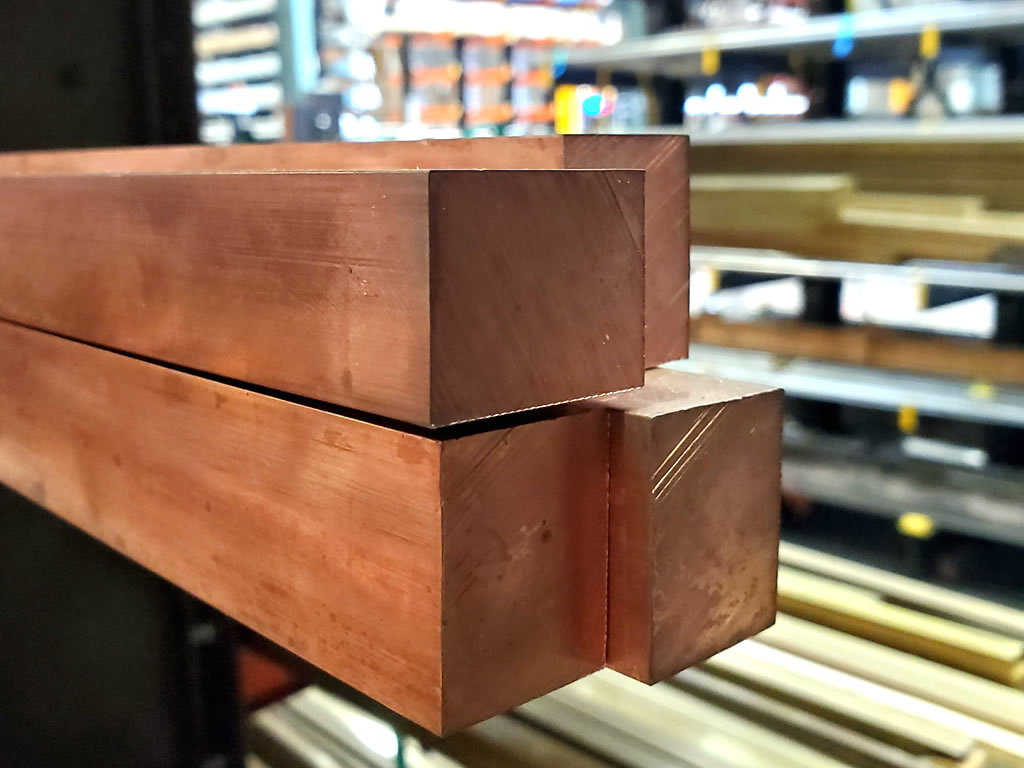

C101 Copper (CW004A)

With high thermal conductivity, C101 (CW1004A) is a popular choice for all types of electrical components and conductors and finds use in a wide range of engineering applications.

C101 is a highly versatile material that we typically supply as HDHC (hard drawn, high conductivity) and offers high ductility and impact strength. It is a popular alloy for various electrical conductors and components. C101 (CW1004A) is 99.9% pure and forms the basis of many brasses and bronzes.

Benefits:

Typical commercial applications include:

- Excellent for soldering

- Versatile - widespread uses

- High ductility and material strength

- Corrosion resistance is good to excellent

Use in Electronics

Due to the alloy's high conductivity, C101 finds extensive use in applications with electrical currents. Transformers, terminals, busbars, motors, heatsinks and windings utilise this copper as a conducting material.

Architectural Applications

The alloy also finds favour from architects who specify copper as a corrosion-resistant engineering material for building fascias and structures. As the material reacts with the atmosphere, the surface forms a copper-green oxidised layer (or patina), which is aesthetically pleasing to the eye.

Stock Range

We stock C101 copper alloy in round, flat and square bars. We also carry sheet stock.

Other Characteristics

The product provides excellent joining capabilities by soldering, good ductility and high impact strength.

Product Summary

| Product | C101 |

|---|---|

| Type | Copper Alloy |

| Availability | Round bar, flat bar, square bar and sheet |

| Benefits | Excellent for soldering, versatile - widespread uses, high ductility and material strength, corrosion resistance is good to excellent |

| Applications | Connectors, transformers, general electronics, motor components, busbars, cable strips, heatsinks, building fascias |

| Datasheet | C101 - Technical Datasheet |

| Reference | Home/ Products/ Copper Alloys/ C101 |