Vinyl Coating Services

Our vinyl coating service allows us to add a protective coating to a range of sheet and plate materials.

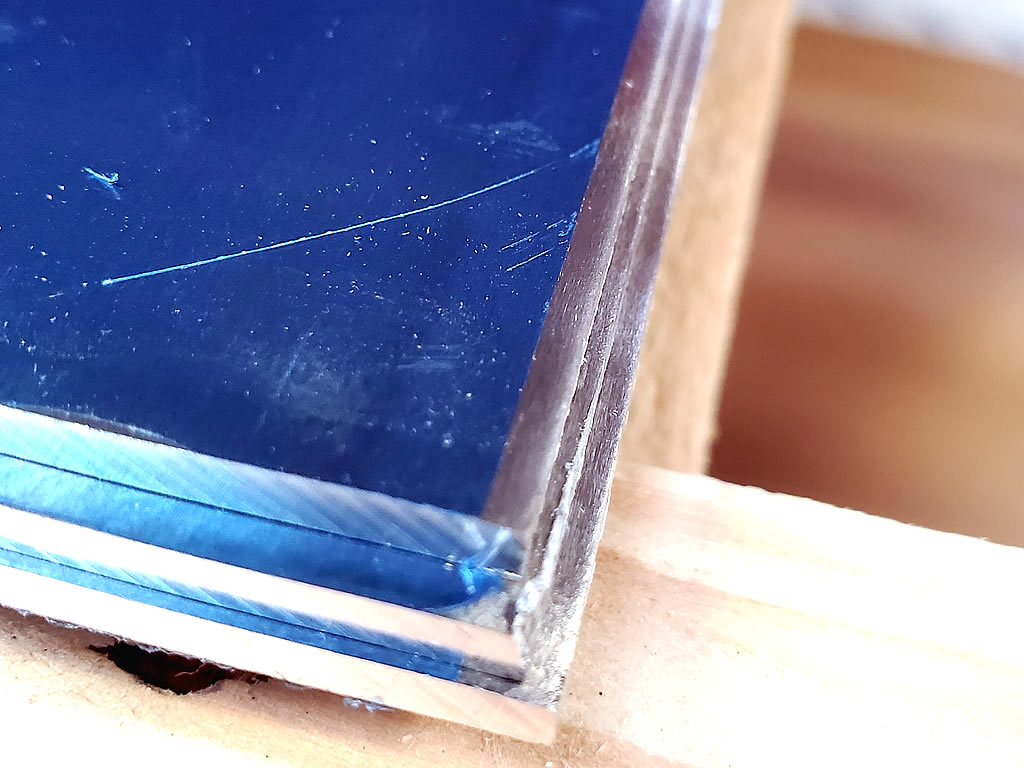

We recommend this service for any application where an aesthetic surface finish is essential, and there is a risk of surface damage during fabrication. In addition, the vinyl coating is sometimes used where lubrication is required during bending or shallow forming operations.

Our Services

Standard vinyl coating service:

- Min. sheet thickness 26 SWG 0.45mm

- Max. sheet thickness 1/2" 13mm

- Normal Coatings: thickness 0.002" (0.05mm)

- Heavy Duty Coatings: - thickness 0.004" (0.10mm)

Operations

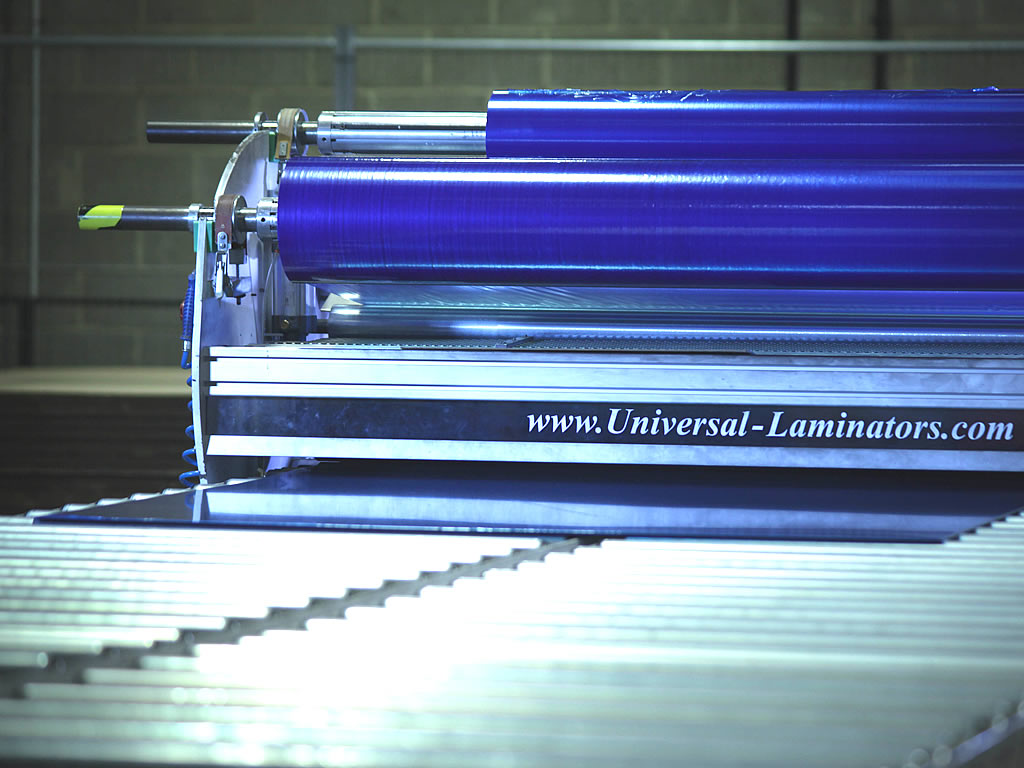

We have invested in a CNC vinyl coating line that allows us to process high volumes where required but with the flexibility to process volumes down to single sheets. During the coating, a very thin layer of adhesive is applied to each sheet that allows the vinyl to be firmly attached and easily removed by hand when it has done its job.

Protection

In some instances, our customers value the product's aesthetic appearance to be of the utmost importance, and our vinyl coating service ensures that you will receive our sheet products in prime condition.

Flexibility in Supply

Our processes can be combined, and there is no limit. So if you want your stainless steel sheets cut via our guillotining service and vinyl coated afterwards, this is not an issue.

Talk to Us

Give Thames a call on 020 8805 3282, and a member of our sales team will be happy to assist you further.

Processing Services

| Type | Vinyl Coating |

|---|---|

| Services | Protective film for sheet products |

| Thickness | Min: 26 SWG (0.45mm), Max: 1/2" (13mm) |

| Coatings (normal) | 0.002" (0.05mm) - blue, green, normal duty |

| Coatings (Heavy) | 0.004" (0.10mm) - black or white, heavy duty |

| Info Sheet | Thames Processing Info Sheet |

| Reference | Home/ Processing/ Vinyl Coating |