UNS S17400 (AMS 5643)

UNS S17400 (AMS 5643) is hardened by a single low-temperature precipitation hardening treatment and contains 4% copper.

After treatment, S17400 offers excellent mechanical properties at a high strength level. The alloy can be magnetised and has a typical density of 7.75kg/ dm³. We also supply AMS 5643, the American specification of this material. The use of UNS S17400 in the annealed condition is not possible.

Benefits:

Typical commercial applications include:

- High-strength alloy with good corrosion resistance

- Suitable for the manufacture of intricate parts

- Excellent weldability

- Excellent mechanical properties after treatment Applications Missile

Corrosion Resistance

UNS S17400 offers suitability in environments requiring good strength with moderate corrosion resistance. The material offers similar corrosion resistance 304 stainless steel and is generally superior when compared to 400 series stainless steels.

Applications

UNS S17400 finds use in engineering applications, including missile components, motor shafts, aerospace and defence components, gears and valve stems.

Weldability

The weldability of the alloy is good via standard welding methods.

Stock Availability

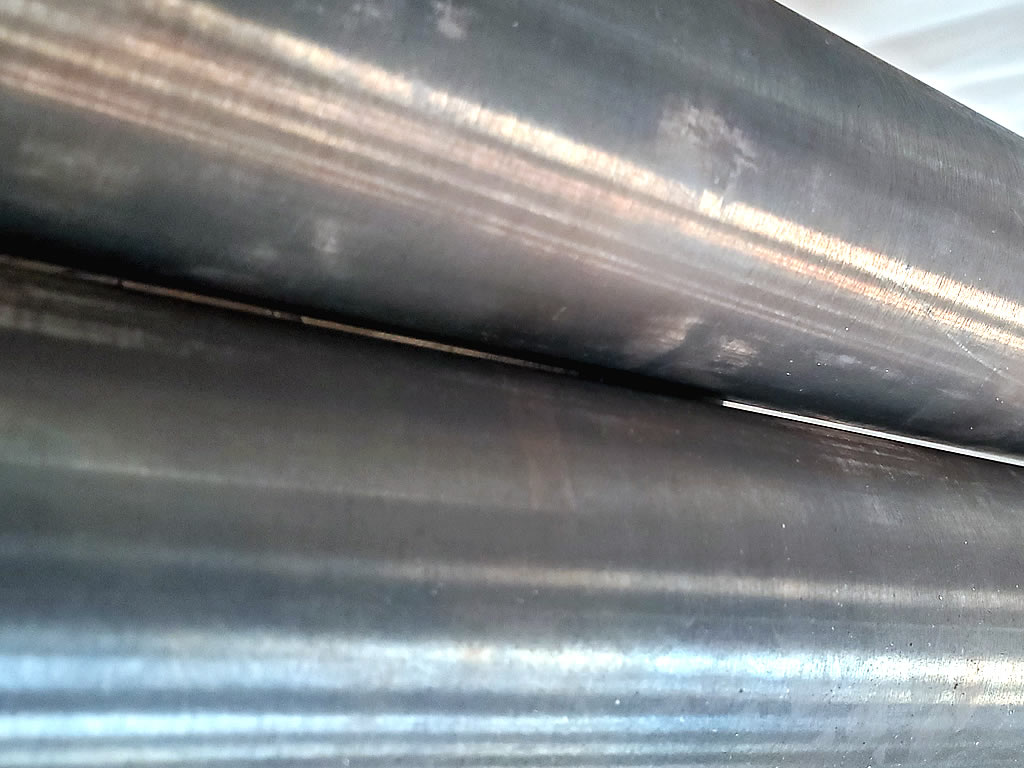

We stock UNS S17400 in round bars and plates, which we also process on-site to your size requirements.

Product Summary

| Product | UNS S17400 |

|---|---|

| Type | Precipitation Hardened |

| Availability | Round bar and plate |

| Benefits | High-strength alloy with good corrosion resistance, suitable for the manufacture of intricate parts, excellent weldability, excellent mechanical properties after treatment |

| Applications | Missile components, motor shafts, aerospace and Defence components, gears, valve stems |

| Datasheet | UNS S17400 - Technical Datasheet |

| Reference | Home/ Products/ Stainless Steels/ UNS S17400 |