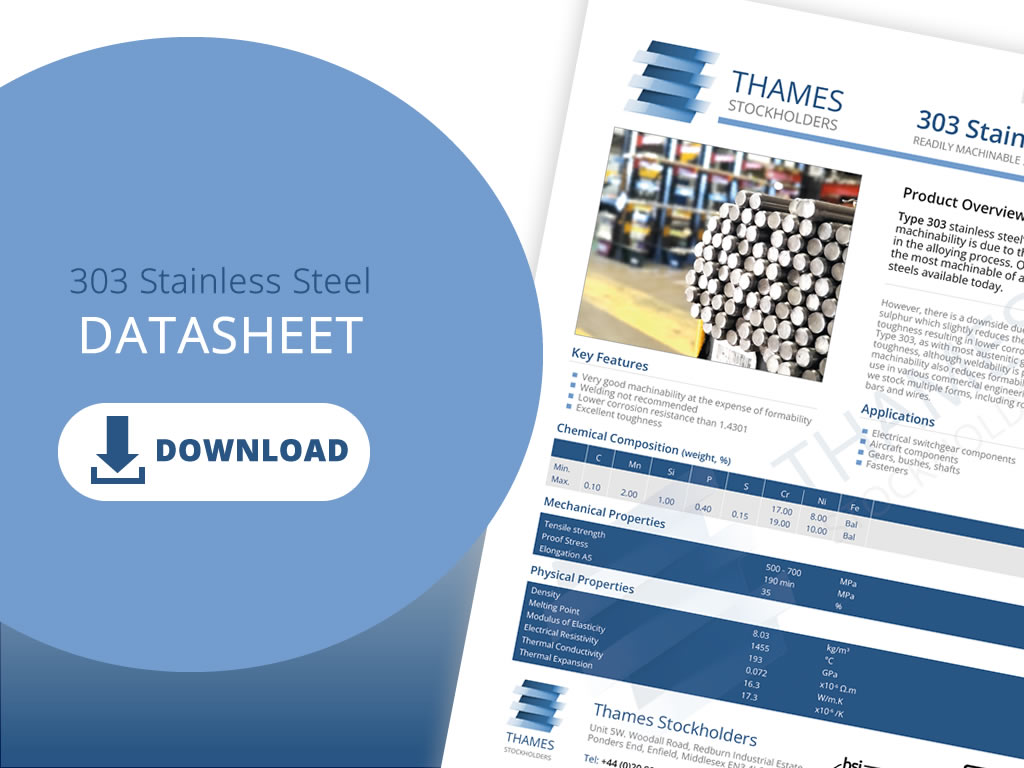

303 Stainless Steel

Type 303 stainless steel's improved machinability is due to the presence of sulphur in the alloying process.

Our product is one of the most machinable of all austenitic stainless steels available today. However, there is a downside due to the presence of sulphur which slightly reduces the alloy's overall toughness resulting in lower corrosion resistance.

Features:

Typical commercial applications include:

- Very good machinability at the expense of formability

- One of the most popular stainless steels

- Excellent toughness

- Cost-effective

Other Characteristics

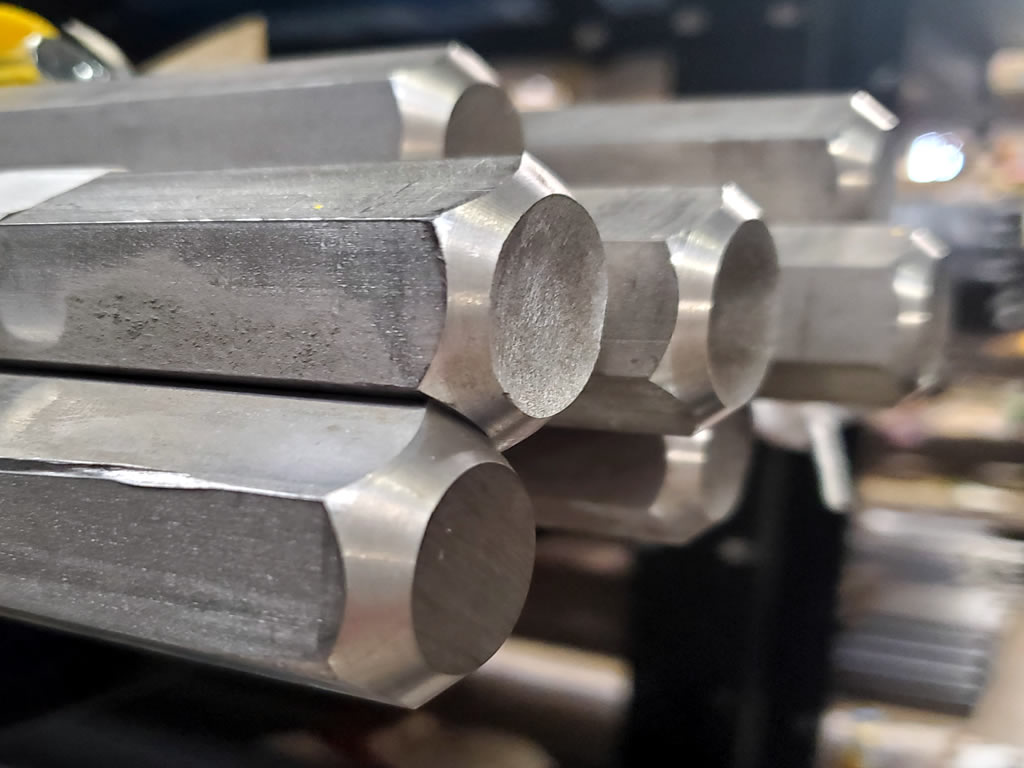

Type 303, as with most austenitic grades, has excellent toughness, although weldability is poor. Improvement in machinability also reduces formability. The material finds use in various commercial engineering applications, and we stock multiple forms, including round bars, hexagonal bars and wires. The material is also non-magnetic and offers an excellent solution for heavily machined components.

Applications

Type 303 stainless steel finds use in commercial engineering applications including electrical switchgear components, aircraft components, gears, bushes, shafts and fasteners.

Popularity

303 stainless steel is one of the most popular stainless steel alloys on the market. The material is cheaper than many low-carbon steel products but offers attractive performance benefits. The alloy is readily machinable and finds use in various industries, including aerospace and household appliances.

Availability

We stock different forms including round bars, hexagonal bars and wires.

Product Summary

| Product | 303 |

|---|---|

| Type | Readily machinable stainless steel |

| Availability | Round bar, wire and hexagon |

| Benefits | Very good machinability at the expense of formability, excellent toughness |

| Applications | Electrical switchgear components, aircraft components, gears, bushes, shafts, fasteners |

| Datasheet | 303 - Technical Datasheet |

| Reference | Home/ Products/ Stainless Steels/ 303 |