2014 Aluminium

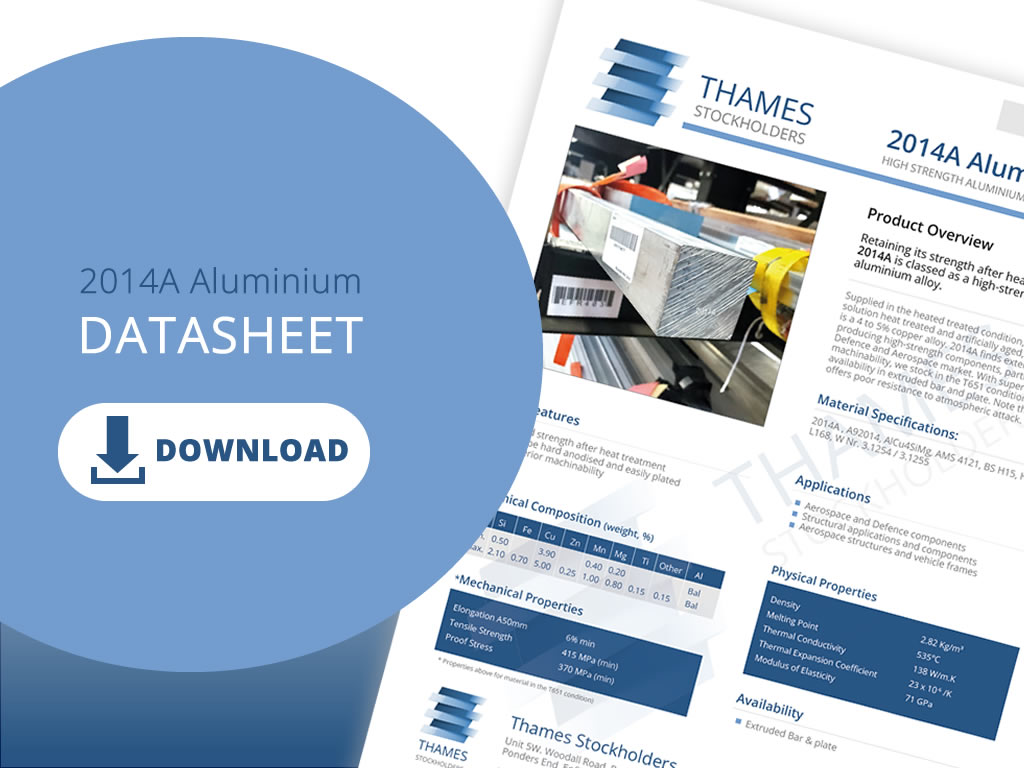

Retaining its strength after heat treatment, 2014A is classed as a high-strength aluminium alloy.

Supplied in the heated treated condition, which is solution heat treated and artificially aged, the material is a 4 to 5% copper alloy. 2014A finds extensive use in producing high-strength components, particularly in the Defence and Aerospace market. With superior machinability, we stock in the T651 condition with availability in extruded bar and plate. Note that the alloy offers poor resistance to atmospheric attack.

Benefits:

Typical commercial applications include:

- Good strength after heat treatment

- Can be hard anodised and easily plated

- Superior machinability

- For high-strength components

Corrosion Resistance

The material offers poor corrosion resistance, particularly to atmospheric attack, and therefore hard anodising should be considered where additional protection is required. A light coat of lanolin will also protect the alloy from atmospheric corrosion.

Weldability

2014A offers excellent weldability when using beam, spot and resistance welding methods. Brazing and soldering are not recommended.

Applications

The alloy finds typical use in commercial structural applications such as aerostructures and vehicle frames. 2014 is also a popular alloy for aerospace and defence components production.

Availability

We stock 2014A aluminium alloy in extruded bar and plate.

Product Summary

| Product | 2014A Aluminium |

|---|---|

| Type | High Strength Aluminium |

| Availability | Bar and plate |

| Benefits | Good strength after heat treatment, can be hard anodised and easily plated, superior machinability |

| Applications | Aerospace and Defence components, structural applications, aerospace structures |

| Datasheet | 2014A Aluminium - Technical Datasheet |

| Reference | Home/ Products/ Aluminium Alloys/ 2014 |