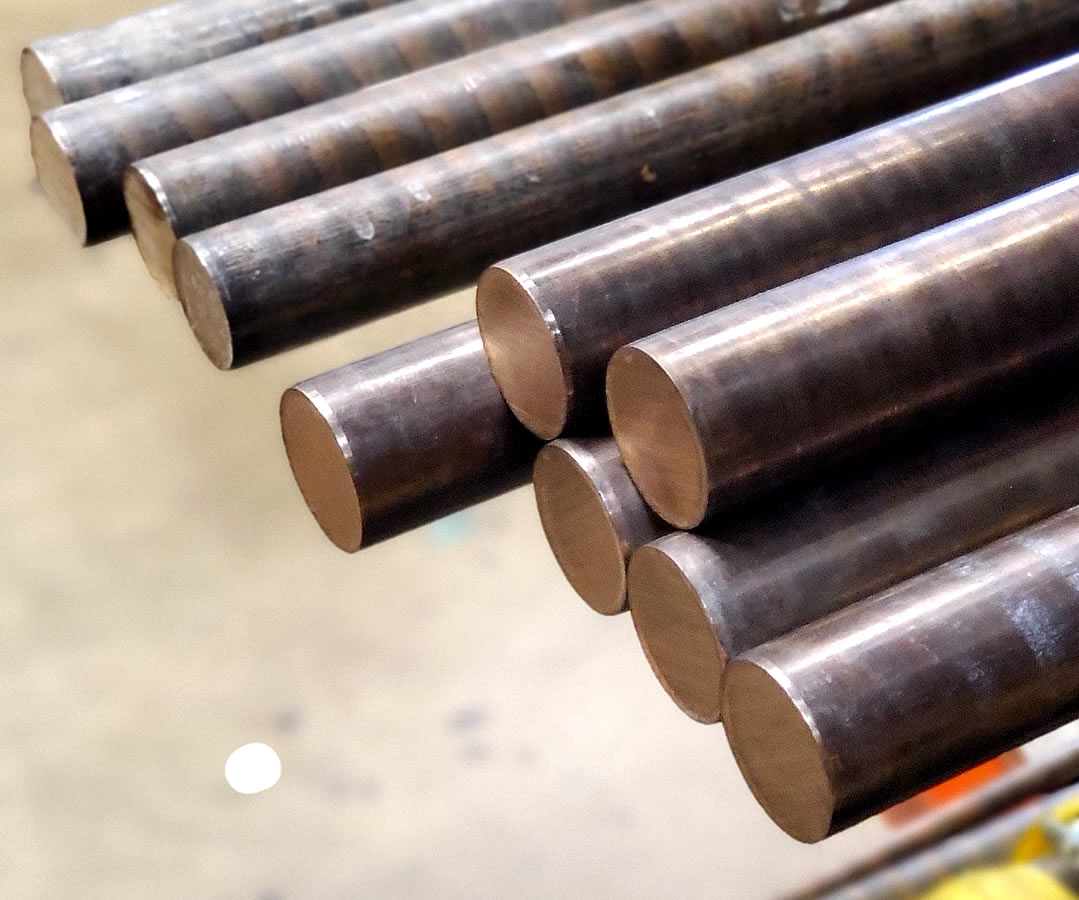

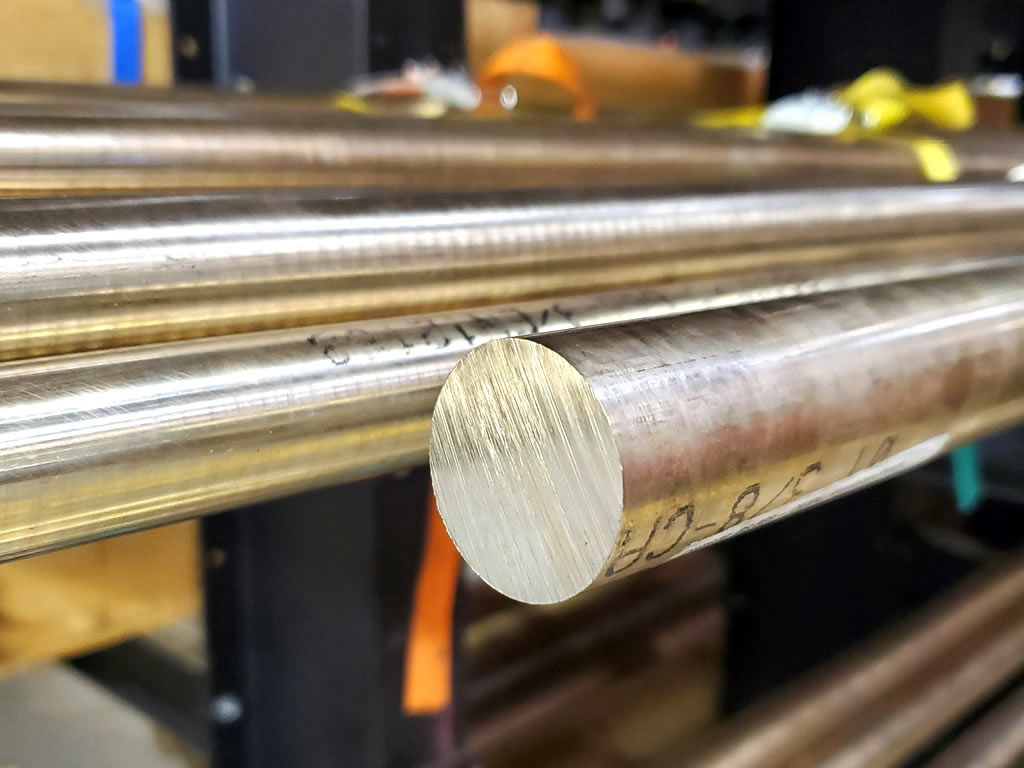

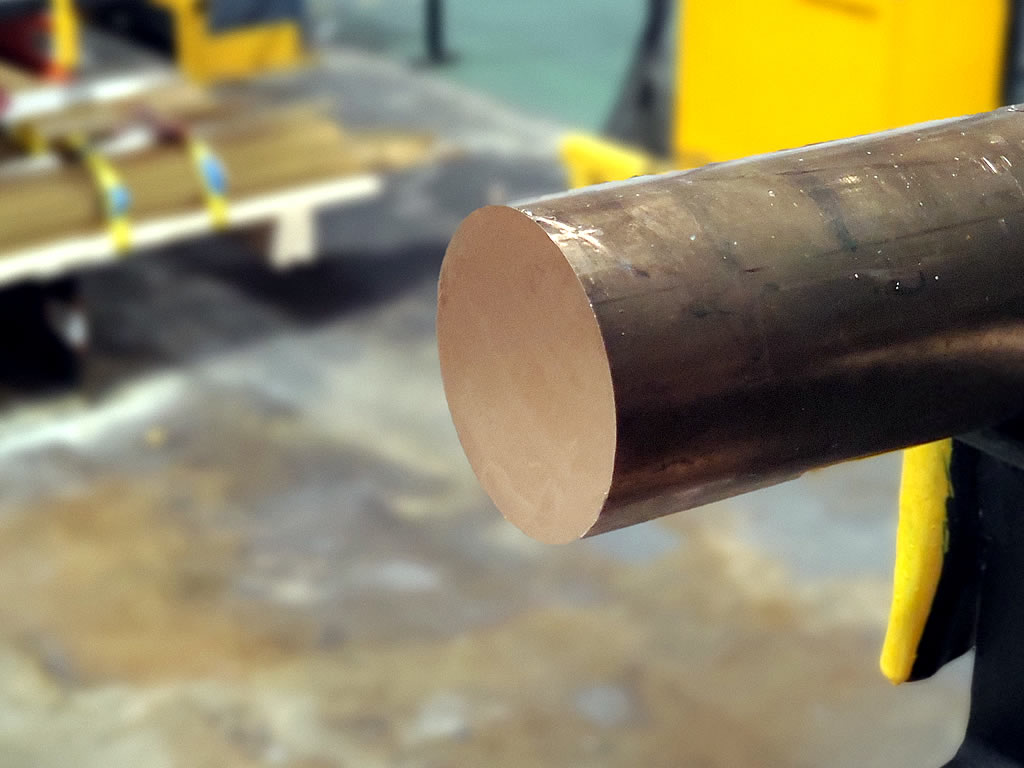

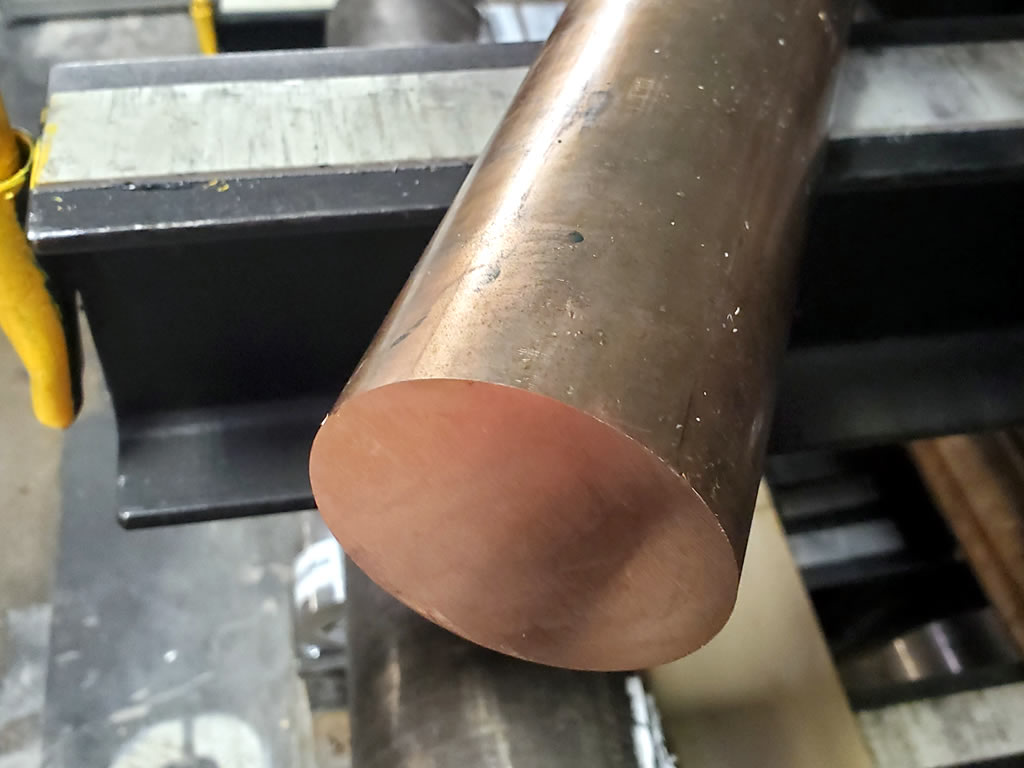

About Aluminium Bronze

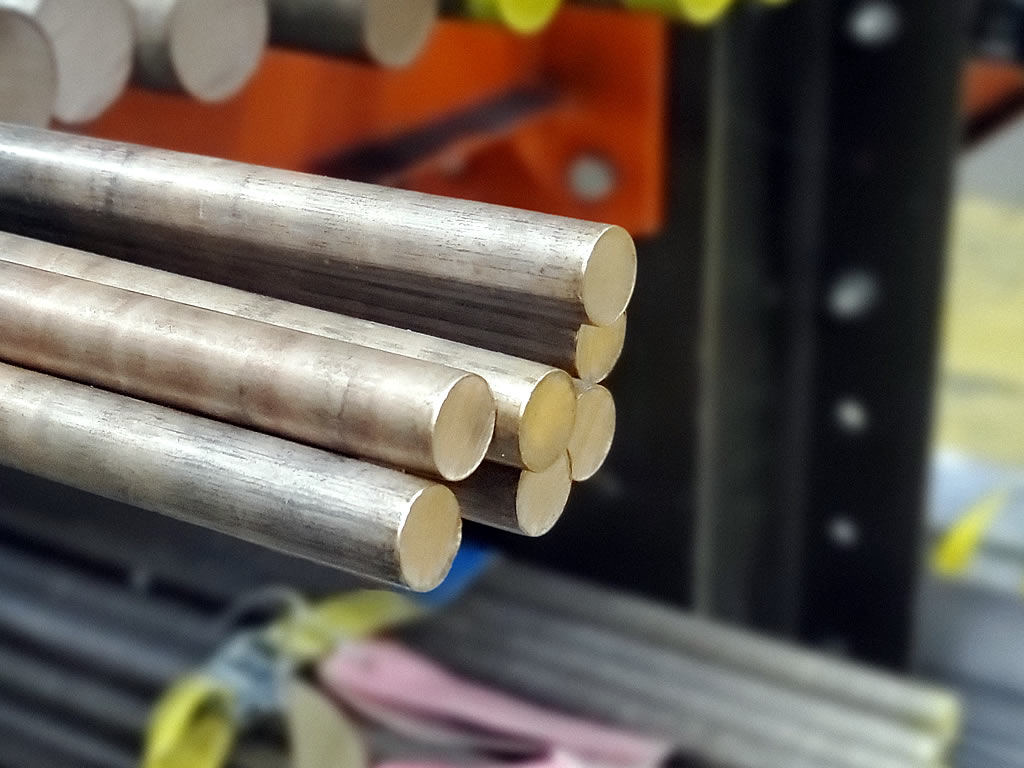

Aluminium bronze is a relative newcomer and has proved to be a popular product for subsea applications, military manufacture and avionics.

The alloy offers excellent corrosion resistance in chloride and saltwater environments. With high strength and tremendous shock and wear resistance, aluminium bronze also retains these properties at cryogenic temperatures.

Our products offer similar strength characteristics to mild steel and represent the strongest copper-based alloys. The alloy also naturally limits the effects of algae, barnacles and muscles in seawater, making it ideal in marine environments.

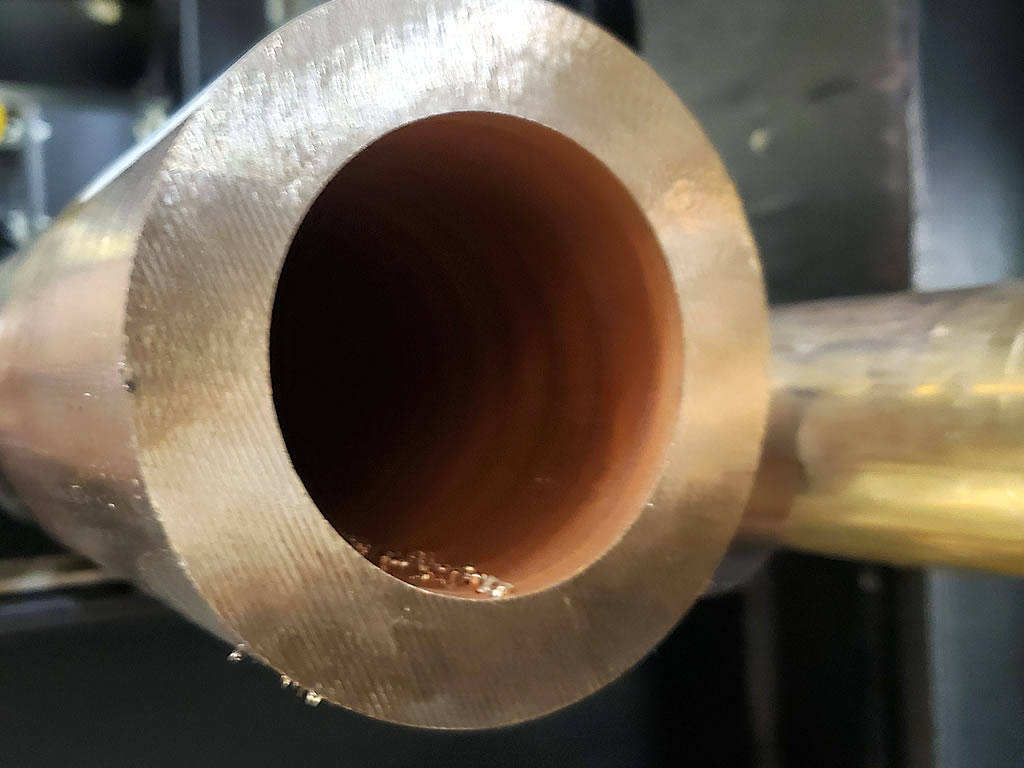

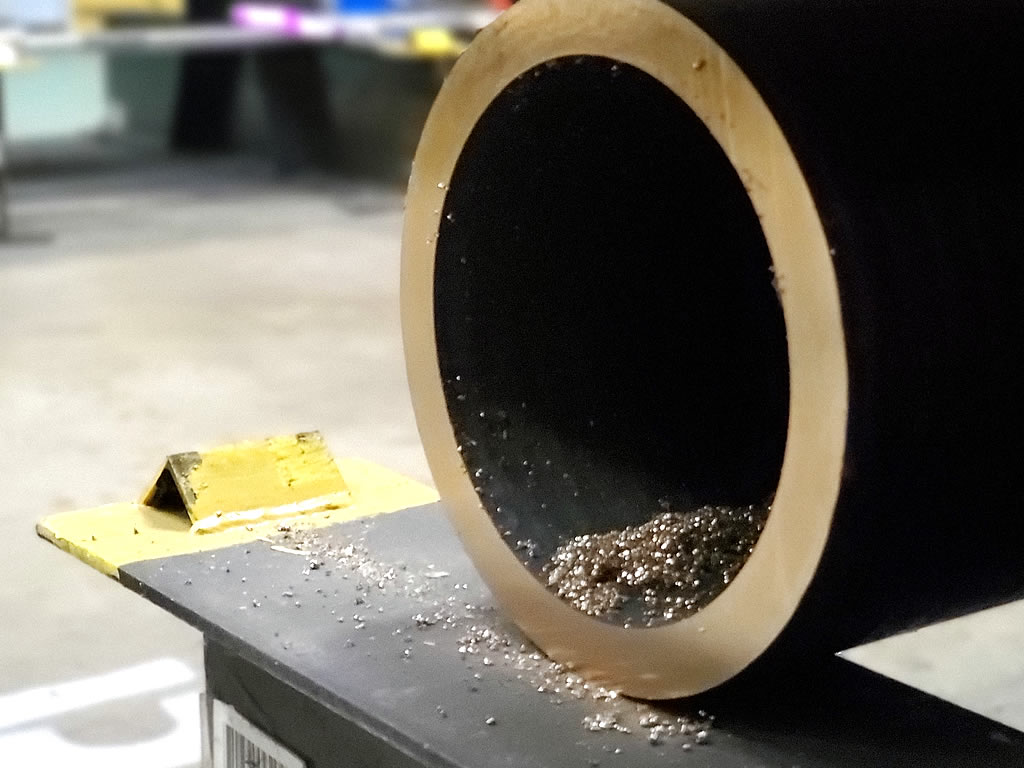

Aluminium bronzes find use in marine hardware, engine components, bushes, bearings and pump components.

We stock aluminium bronze alloys, including CA104.