A Viable Alternative

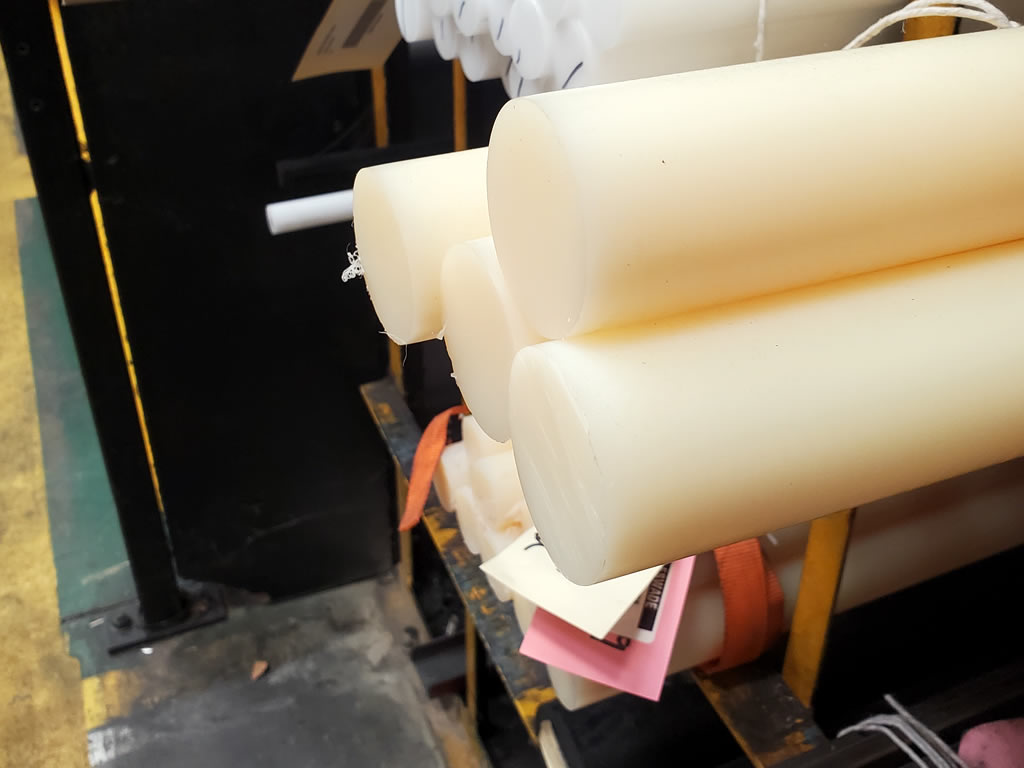

Engineering plastics are often considered a viable material alternative for designers seeking specific performance parameters.

Considering plastics solely as a general engineering product would be a mistake. Our products find use in many high-technology industries where the performance and specification of our materials often surpass more traditional alloys.

Automotive serves as a good example. Not so long ago, bumpers were manufactured from steel with chromium plating. Today, bumpers are almost exclusively produced in plastic, which is just as strong but considerably lighter.

Plastics offer beneficial characteristics such as good strength-to-weight ratios and can be reinforced with other compounds to promote unique benefits. Automotive, motorsport and aerospace are all markets benefitting from high-performance engineering plastics.

Our plastics range meets the stringent demands of modern industry.